Friday, November 26, 2010

Bihar result,eye opener to national parties

Bihar election results are eye opener to all parties and especially to national parties like Congress and BJP.It was a herculean task to rule Bihar after a long Jungle Raj of Lalu. I had been following the development of Bihar closely during all these years of Nitish Kumar.What i found was that he was sincere and willing to perform.He chose a team of such IAS officers who were men of integrity and performers and of course achievers. He himself being clean could get the desired results from his team.

What is expected from Congress and BJP now is to find one such person in country in UP who is qualified engineer with management degree /economist from top institutes willing to work sincerely, interested in politics and service to common man and coming from a grass root family.If they have some person in their party which Rahul Gandhi or Sushma Swaraj may find in their parties, he may be groomed and projected as leader of their party for next state elections due in 2012. Only the development plank and realistic future vision can bring the party to power.Junta is matured enough as we saw in High Court judgment in RJBM case.

Monday, November 15, 2010

Energy from Algae - A ray of hope for the Power Hungry World

Petrochemical resources are limited and are bound to be scarce in the times to come. Also, due to their adverse impact on the environment, which has lead to a widely discussed phenomenon of global warming, the use of these fossil fuels has to be reduced by both the developed as well as the developing world.

Development of CO2-neutral sustainable fuels thus becomes a high priority in the research regimes across the world. Energy generation from certain plants like rape or oil palm may not be the best option as these may also be used for food production. Thus Hydrogen, which is used by fuel cells to generate electricity, could be a likely winner due to absence of green house gas generation in fuel cell technologies. Some energy experts have even gone to the extent of predicting that within decades the world will switch to a purely hydrogen driven existence, where energy will be abundant, inexpensive and nonpolluting.

Hydrogen can be extracted from fossil fuels, but currently it is more expensive than directly using oil or natural gas. Water can also be split into hydrogen and oxygen through electrolysis, but that requires electricity, which again might be generated using fossil fuels, or from renewable sources such as wind or solar that are even more costly.

High oil prices, competing demands betw een foods and other Biofuel sources, and the world food crisis, have hence ignited interest in alga culture (farming algae) for making vegetable oil, Biodiesel, Bio-ethanol, Bio-gasoline, Bio-methanol, Bio-butanol and other Bio fuels, using land that is not suitable for agriculture.

een foods and other Biofuel sources, and the world food crisis, have hence ignited interest in alga culture (farming algae) for making vegetable oil, Biodiesel, Bio-ethanol, Bio-gasoline, Bio-methanol, Bio-butanol and other Bio fuels, using land that is not suitable for agriculture.

Microalgae are mono-cellular, plant-like organisms engaged in photosynthesis and converting carbon dioxide (CO2) into Biomass. Algal Biomass contains three main components: carbohydrate, protein, and natural oils. Therefore, it is capable of producing a number of potential fuels, such as production of methane gas via biological or thermal gasification, production of ethanol via fermentation, production of Bio-diesel, and the direct combustion of the algal Biomass for production steam or electricity.

Recent research initiatives have proven that microalgae Biomass appear to be the one of the promising source of renewable Bio-diesel capable of meeting the global demand for transport fuels. Microalgae commonly double their Biomass within 24 hours and with high oil productivities, they are highly desired for producing Bio-diesel. Using microalgae to produce Bio- diesel will also not compromise production of food, fodder, and other products derived from crops. More over, energy generation from microalgae is largely CO2 neutral as they take up CO2 during their growth and this CO2 is later released again when they are used for energy production. Industrial CO2 emissions may also be used as a "re-source", as algae grow faster at high CO2 concentrations and, hence, produce more Biomass for energy production. The algae could well be used in waste water treatment and can be grown in different environments in both fresh and salt water.

Cultivation of microalgae has thus emerged as one of the most promising sources for Bio-oils that may significantly contribute to tomorrow's energy supplies.

John Gartner, in his article " Algae : Power Plant of the future?" tells that Hans Gaffron, a German researcher who fled from Germany to University of Chicago in the 1930 observed in 1939 that the algae would (for a then-unknown reason )sometimes switch from producing oxygen to instead creating hydrogen, but only for a short period of time.

Under normal circumstances, algae contain mainly hydrocarbons and proteins; the fat content does not exceed 20% of the total dry weight. But in 1980 it was discovered that under nutritional stress limited nutrients or saline environment certain microalgae will accumulate up to 72% of their weight as lipids (fatty substances).A typical algal mass has a heating value (heat produced by combustion) of 8,000-10,000 BTU/lb, which is better than lignite; but the heating value of algal oil and lipids is 16,000 BTU/lb, which is better than anthracite. A breakthrough finally came only 60 years later in 1999, when University of California at Berkeley professor Tasios Melis, along with researchers from the National Renewable Energy Lab, discovered that depriving the algae of sulfur and oxygen would enable it to produce hydrogen for sustained periods of time.

Source: http://cepweb.wordpress.com/2010/05/30/promising-new-research-on-cellulosic-ethanol/

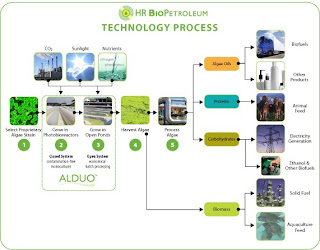

The concept of extraction of Biodiesel from algae is shown in the image alongside.

Dr Shakeel A Khan, Scientist, Indian Agri research institute explains in his article “Algae -a novel source of renewable energy and carbon sequestration” that there are two practical and very common methods of large-scale production of microalgae.

Raceway ponds: It is a closed loop re-circulation channel that is typically about 0.3 m deep. There is a paddlewheel, which mix and circulate the algal Biomass. Flow is guided around bends by baffles placed in the flow channel. Raceway channels are built in concrete or compacted earth, and generally lined with white plastic. During daylight, the culture is fed continuously in front of the paddlewheel where the flow begins. Broth is harvested behind the paddlewheel, on completion of the circulation loop. The paddlewheel operates all the time to prevent sedimentation.

Photo-Bioreactors (PBs): PBs have been successfully used for producing large quantities of micro algal Biomass. PBs permit essentially single-species culture of microalgae for prolonged durations. Tubular PB consists of an array of straight transparent tubes that are usually made of plastic or glass. The solar collector tubes are generally 0.1 m or less in diameter. Tube diameter is limited because light does not penetrate too deeply in the dense culture broth that is necessary for ensuring a high Biomass productivity of the PB. Micro algal broth is circulated from a reservoir to the solar collector and back to the reservoir.

The potential of microalgae for making liquid fuels has led to the creation of hundreds of companies in the field and extensive research is going on for identifying the most efficient and cost effective process for commercial production of Bio oils from algae. In spite of this, there are only a handful of efforts which are close to pilot-scale production of fuels, including Sapphire Energy and Cellena Oil, which is backed partially by Shell Oil.

One of the patented technologies that use a mix of raceway ponds and PBs for production of Bio-fuels from Algae is the HR Bio petroleum Technology. In their pilot plant, a selective strain of algae is grown in a PB at constant conditions that favor continuous cell division and prevent contamination of the culture by other organisms. The main body of the production PB is a long series of four large temperature and pH controlled tubes that are connected together in parallel. The algae are exposed to sunlight while kept in suspension to maximize growth. Subsequently, the algae are transferred from the PBs to an open pond system, which is paddlewheel-driven, re-circulating raceway, fitted with a durable plastic liner. The goal here is to expose the cells to nutrient deprivation and other environmental stresses that lead, as rapidly as possible, to synthesis of Biodiesel. Environmental stresses that stimulate oil production can be applied rapidly by transferring culture from the PB to an open pond. Ponds, like PBs, are exposed to full sunlight. Depending upon the desired product, the pond is harvested on 2nd or 3rd day and the algae cells are concentrated by gravitation into slurry, excess water is then removed, and then further concentrated by centrifugation. The wet Biomass is then dried. The oil and other by-products are extracted by a proprietary process.

India consumes crude oil at a rate far above its production rate, leaving them reliant on foreign oil supplies. Even if crude oil use was not growing at 5-6% annually, India’s reserves would run out in less than 20 years at current extraction rates. With estimated 70% of petroleum occurring in automobiles, developing liquid alternative fuels usable in vehicles is vital, making Bio-fuels an attractive option. Howe ver, producing crop-based fuels in a country so densely populated, with such poor food security and limited arable land, would be difficult and dangerous. Table alongside compares the capacity of Bio fuels generation from different sources. According to “Biodiesel 2010 – A global Market survey” , India has up to 60 million hectares of non-arable land available to produce jatropha, and intends to replace 20% of diesel fuels with jatropha-based biodiesel. India is already one of the world’s biggest producers of algae and this alternative could prove particularly valuable for India where current commercial production is generally for human consumption. Biodiesel from algae can be interchanged or mixed with regular diesel, the main vehicle fuel in India.

ver, producing crop-based fuels in a country so densely populated, with such poor food security and limited arable land, would be difficult and dangerous. Table alongside compares the capacity of Bio fuels generation from different sources. According to “Biodiesel 2010 – A global Market survey” , India has up to 60 million hectares of non-arable land available to produce jatropha, and intends to replace 20% of diesel fuels with jatropha-based biodiesel. India is already one of the world’s biggest producers of algae and this alternative could prove particularly valuable for India where current commercial production is generally for human consumption. Biodiesel from algae can be interchanged or mixed with regular diesel, the main vehicle fuel in India.

Extensive research is also on to identify specific strains of algae and to develop processes and technologies, wherein Bio-fuels from algae may be directly used in transportation, rather than blending them with fossil fuels.

But the battle has just started. The 2nd edition of the Biodiesel 2020 study finds the biodiesel industry is entering a new era of transition to alternative feed stocks, emerging technologies, and revised government policies favoring sustainable feed stocks and fuels. Each of these transitions offers considerable challenges and growth opportunities for biodiesel developers, producers, feedstock producers, and entrepreneurs.

On the other hand, according to US Energy & Policy Advisor Daniel Kammen, the most interesting feature about algae is that it’s a wildcard. Algae might be a big player, but right now, there are some real breakthroughs required for a reasonable sized scale of production of algae-oils, sufficient to run even a car. According to Christen Coogner of Discovery news, although algae is currently the most energy-dense Bio fuel source, the cost of producing algae oil is prohibitively expensive. The U.S. Department of Energy estimates that the Bio fuel would cost around $8 per gallon at the pump. Other experts have even projected prices of more than $50 per gallon because of inefficient production and harvesting methods.

Kansas State University engineer Wenquiao Yuan and his colleague think that growing algae on floating, acre-sized platforms in the ocean could dramatically reduce expenses associated with algae oil production by providing free sources of sunlight, nutrients, controlled temperature and water. However, the ocean environment could present some unavoidable problems – like weather extremities.

Some reports even suggest that it will be at least 10 – 15 years before we can hope to have found a satisfactory solution to this end. Thus the future of commercial scale production of Bio-fuels and energy from algae is still unclear. While the research and pilot tests will continue and even more funds and resources will be committed and deployed, the world at large should continue building emphasis on energy conservation and efficient utilization of electrical as well as thermal energy. We must acknowledge that at present it is far cheaper and easier to conserve energy than to generate more from renewable sources and the environmental impact of ever increasing generation from fossil fuels is already there for the world to see.